Gas separation

Efficient biogas upgrading with SEPURAN® Green membranes made by Evonik

Evonik has developed an innovative membrane technology for upgrading biogas into biomethane. With SEPURAN® Green membranes, the biomethane can be purified from the raw biogas to over 99%.

Evonik has developed a biogas upgrading process that makes best use of the membranes' separation properties: Through skillful connection of SEPURAN® Green membranes it is possible to obtain methane with a purity level of up to 99% from the crude gas. Just one compressor is needed.

SEPURAN® Green membranes have the highest CO2/CH4 selectivity and are therefore a superior technology for upgrading biogas. This selectivity of the membranes enables the production of high purity biomethane with superior methane recovery. This distinguishes the Evonik membranes from other membranes that are available.

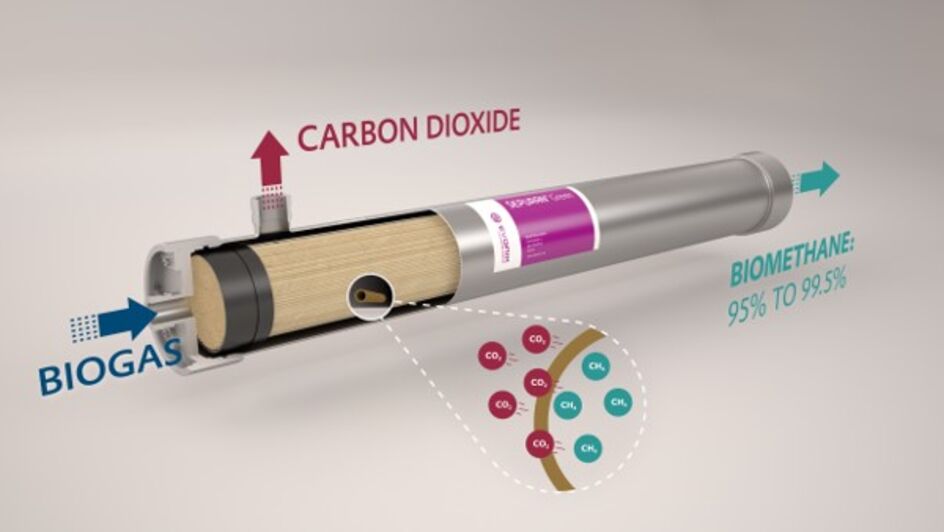

Biogas comes from the biogas plant as a mixture of CO2, methane and the typical secondary components, and is first desulfurized, filtered and pre-dried with activated carbon. The pre-treated gas is then compressed to 10 - 20 bar, and upgraded to biomethane and a CO2-rich waste gas flow using several membrane stages.

How does biogas upgrading with Evonik's SEPURAN® Green membranes work?

Benefits of SEPURAN® Green membrane technology

- Superior separation performance leading to compact plant designs and lower number of membranes

- High energy efficiency (through superior selectivity)

- High chemical and mechanical robustness of membrane

- Proven membrane lifetime of over 10 years à performance easy to recover in case of contamination, membrane itself is maintenance free

- Technical service platform with fast response times globally

- Make-to-stock strategy to guarantee short lead times

Compared with other biogas upgrading processes such as pressurized water scrubbing, pressure swing adsorption, or amine scrubbing, Evonik's membrane technology has significant advantages: It requires comparatively little energy and does not need any auxiliary materials or chemicals. No waste or wastewater is produced that would otherwise have to be treated and disposed of.

Upgrading of Biogas to Biomethane with SEPURAN® Green Membranes

Biogas is produced by the fermentation of biomass - an organic substance, for example, from waste such as liquid manure and sewage sludge or from renewable raw materials. The particularly selective SEPURAN® Green hollow-fibre membranes from Evonik easily and efficiently upgrade raw biogas, which consists of the energy carrier biomethane plus carbon dioxide, into high-purity biomethane. The climate-friendly energy source can consequently be used to generate electricity and heat or used as a fuel. The membranes are made of a high-performance polymer specially developed by Evonik that is highly resistant to pressure and temperature.

In addition to the SEPURAN® Green membranes, Evonik has also developed and patented a 3-stage biogas upgrading process that makes optimum use of the membranes' separation properties:

Evonik has also developed tools to improve plant designs to gain best possible purities. In addition to that we offer best-in-class technical service to ensure plant performance even in challenging environments and a technical service platform globally with fast response times.

As a specialty chemicals company we have the expertise in-house to design the polymers according to your customers and market needs.

Trash, manure, and wastewater have lots of potential. The biogas extracted from them with the help of high-performance membranes from Evonik provides energy carriers and valuable raw materials for industry. A plant in the South Tyrol shows on a small scale how a problem can become a profitable solution for everyone involved.