Forward-looking solution for strong adhesion and excellent properties in a wide range of adhesive and sealant systems

Benefits at a Glance

- Alternatives with reduced VOC content

- Formulation of environmentally friendly and label-free end products

- Excellent adhesion and cohesion properties

- Suitable for a wide range of adhesive and sealant systems

- Increased storage stability

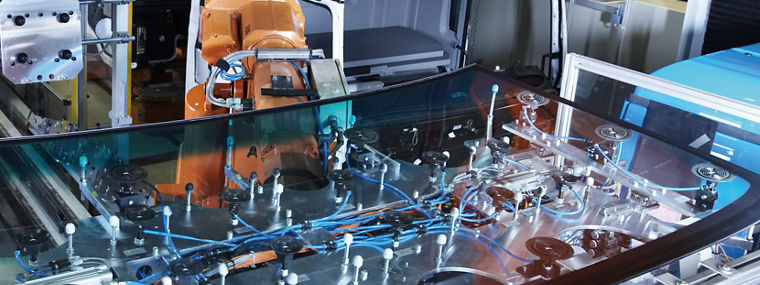

Industries such as transportation, construction, and industrial assembly require adhesives and sealants of exceptional quality that can endure even the most challenging conditions, while providing a strong and long-lasting bond. Up to now, Dynasylan® GLYMO has often been used in these formulations as an adhesion promoter and crosslinker, with additional positive effects on the mechanical properties and processing characteristics of the end product.

The adhesives and sealants industry is currently searching for substitute materials to replace Dynasylan® GLYMO, as the ingredient glycidyloxypropyltrimethoxysilane is undergoing increased scrutiny within the market.

Evonik now provides a range of next-generation silane additives that exhibit superior performance compared to Dynasylan® GLYMO in certain applications. Some of these new additives are specifically designed to be environmentally friendly.

Two functional silanes, VPS 7163 and VPS 4721, are highly effective additives that can be utilized across a range of systems to enhance both adhesion and mechanical properties of the final products.

VPS 7163 provides excellent adhesion to aluminum

VPS 7163 is an excellent adhesion promoter and crosslinker suitable for 1K and 2K polyurethane and silicone adhesives, acrylates, SMP systems, and many other adhesives and sealants. In tensile shear strength tests, the strength of a 2K polyurethane adhesive with VPS 7163 was tested against Dynasylan® GLYMO as an additive. The results showed that the adhesive bond with the additive VPS 7163 demonstrated a superior resistance to shear forces on aluminum, with an improvement of over twelve percent compared to the bond with Dynasylan® GLYMO. The values are also better on stainless steel and polystyrene.

VPS 4721 helps avoid labeling for adhesive and sealant joints

VPS 4721, a novel epoxy-functional silane oligomer, is eminently suitable for use in 1K/2K epoxy, 1K/2K polyurethane, and acrylates, as well as in water-based and various rubber-elastic systems (including polysulfide, butyl. Furthermore, the use of VPS 4721 adhesive is not only beneficial in terms of performance but also in sustainability. This adhesive helps to reduce VOC emissions by over 60 percent when compared to Dynasylan® GLYMO. Additionally, the use of VPS 4721 adhesive can help avoid the need for GHS labeling on the end product, since the labeling limit for this adhesive is over 30 times higher than that of Dynasylan® GLYMO.

When added to 1K/2K epoxy adhesives, the oligomeric silane produces significantly higher tensile shear strengths on cold-rolled steel and epoxy composites compared to the adhesive containing Dynasylan® GLYMO. The tensile and tear strength of the 1K/2K epoxy adhesives doubles when VPS 4721 is used.

Tests conducted on 1K/2K polyurethane sealants show that the addition of VPS 4721 and Dynasylan® GLYMO as additives produce comparable adhesion results to polycarbonate, but with an improvement in adhesion to aluminum. Tensile shear strengths were found to be 37 percent higher on glass when using VPS 4721 compared to Dynasylan® GLYMO.

In waterborne systems, VPS 4721 also increases the storage stability of the final formulations compared to Dynasylan® GLYMO and leads to significantly increased wet and dry adhesion.