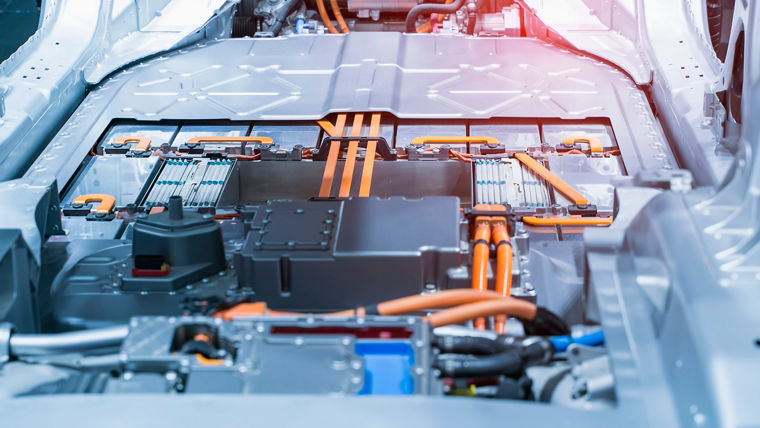

At Evonik, we develop solutions that empower the Battery Industry. Our products are engineered to meet the demands of engineers, specialists, and professionals who are shaping the future of energy storage and battery technology. Our VESTALITE® S 101 curing agents enable optimized epoxy SMC battery technology for structural lightweight applications and ANCAMIDE® and ANCAMINE® curing agents provide excellent adhesive and mechanical properties in EV battery structural adhesives.

For lithium-ion batteries, Evonik's metal oxides, such as AEROXIDE® Alu 65 and AEROXIDE® Alu 130, play a pivotal role. They not only enhance battery safety with a thin ceramic coating on separators but also improve performance and extend battery life by coating the cathode active materials. The TEGO® Surten E product family offers an array of process aids that streamline the mass-production of lithium-ion battery materials, making the production process more efficient and the cells more effective. While our precipitated silica, like SIPERNAT®, serves as a pore creator in PE separators for lead-acid batteries, while Siridion® Black, as an anode additive in lithium-ion batteries, boosts capacity with its stability and oxidation protection.

Further enhancing our portfolio, POLYVEST® EP MV, a liquid polybutadiene, stands out with its high content of 1,2-vinyl double bonds, offering exceptional characteristics such as chemical and water resistance, electrical insulation, and cold resistance. Its compatibility with various resins makes it a versatile choice for applications like electrical insulation and potting compounds. Together with TEGOSTAB®, KOSMOS® and POLYCAT® additives, which are used for adhesives, sealants and potting compounds and to produce polyurethane froth foam for EV battery protection, Evonik is committed to driving innovation in the Battery Industry.

As more batteries reach end of life, recycling LiBs to retrieve their precious materials is even more important and our HYPROX® products use hydrogen peroxide as an eco-friendly recycling agent.

Evonik's PERTRONIC® hydrogen peroxide is designed for the stringent requirements of semiconductor and electronics manufacturing, conforming to SEMI specifications. With grades ranging from 1 to 5+, PERTRONIC® products are trusted by advanced manufacturing sites for their reliability and consistency, catering to a broad spectrum of applications from displays to advanced memory and logic products.

TEGO® Therm makes insulation coatings more efficient by substantially improving the performance of thermal insulation coatings (TICs).

In the realm of high-performance plastics, our flame-resistant VESTAMID® polyamide 12 and VESTAKEEP® PEEK are engineered for use as insulation in battery modules or electric motors, contributing to the safety and efficiency of electric vehicles, while the VISCOBASE® series offers dielectric thermal management fluids for EVs.

Our VESTOPLAST® line of amorphous poly-alpha-olefins is meticulously crafted through a continuous Ziegler low-pressure polymerization process, ensuring polymers with the perfect balance of adhesion, cohesion, and optimal processing characteristics. These polymers not only provide the right melt viscosity but also boast excellent stability and high thermal stability under load, making them ideal as a raw material for automotive hot melt adhesives.

Evonik's specialty chemicals are not just products but solutions that empower the Battery Industry to operate more sustainably, safely, and efficiently. Our commitment to quality and innovation ensures that our partners are equipped with the materials they need to lead the charge in energy storage technology.

Global Presence

- No matching location found

- Error when loading the data. Please try again later.