Together for a Circular Economy

The goal of a circular economy is to create a climate-friendly and resource-efficient economy in which the value of products, materials and resources is retained for as long as possible. For us as a specialty chemicals company, our products and technologies play a crucial role in the transition to a circular economy.

Through our Circular Economy Program (CEP), we work with partners to reach this goal. We go beyond the chemical industry, pooling expertise across markets and the entire value chain. Evonik intends to generate additional annual sales of at least €1 billion from 2030. For us, this is the key to sustainable growth that takes equal account of economic, environmental and social aspects.

Circular Economy at Evonik

Evonik is active in several areas to enable the circular economy. We are expanding our activities in additives and specialties for the circular economy and are increasingly focusing on defossilized raw materials. We are also developing our own closed-loop technologies, for example for the chemical recycling of PET waste streams that cannot be mechanically recycled. Another important area for us is the development of technologies for the use of CO₂ and bio-based raw materials.

Solutions for the entire life cycle

It is important to consider the entire product life cycle. The emphasis lies is on the manufacturing phase, the use phase and recyclability.

In the manufacturing phase, recycled, bio-based or CO₂-based sources are used to replace fossil raw materials. In the use phase, products are characterized by durability, reparability and reusability. To close material cycles, products must be recyclable or biodegradable at the end of their life cycle. This means that less material is sent to landfill or incineration.

Products for the circular economy

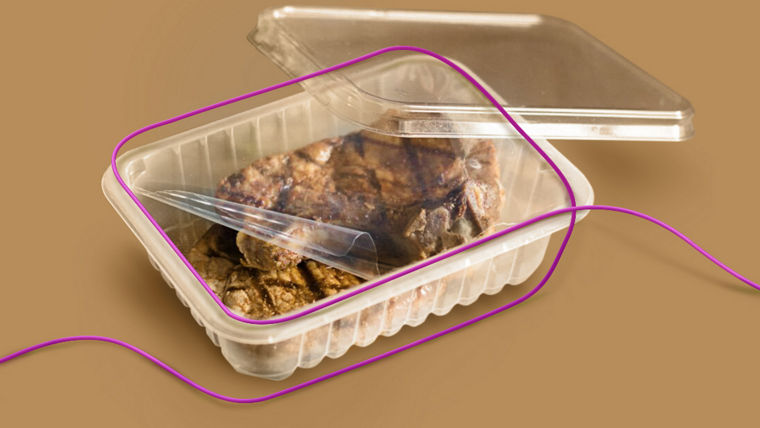

Evonik already offers many solutions for a circular economy throughout the entire life cycle of a product. A heat-sealing binder, for example, makes it possible for packaging materials such as yoghurt pots to be made from a single material and easily recycled. Other examples include a 3D-printed monomaterial concept car seat and a monomaterial toothbrush: polyamide 12 replaces previous material mixtures and facilitates cost-effective and environmentally-friendly mechanical recycling.

In addition to technical solutions, Evonik has started to use bio-based products. Our biosurfactants are pioneering in this field and represent an increasingly important raw material basis for various product ranges, based entirely on renewable raw materials.