Evonik's solutions meet the complex demands of modern manufacturing processes, ensuring high performance, efficiency, and environmental compliance across the Adhesives and Sealants Industry. Our commitment to innovation and sustainability is evident in our diverse product portfolio and broad range of chemical tools.

For those seeking to improve the cohesive strength and resistance of their products, our VISIOMER® methacrylate monomers are indispensable in reactive two-component adhesives and sealants, providing enhanced adhesion to polar substrates.

Crucial for enhancing rheological and mechanical properties, our AEROSIL® fumed silica products ensure stability, anti-sedimentation, and effective processability. AEROSIL® R 202 is ideal for 2-pack epoxy resins, offering an excellent rheology effect for added performance. While AEROSIL® R 208, boasts superb thickening properties and AEROSIL® R 972 offers versatility and improves the shelf-life of silicone sealants.

Our flagship TEGO® Antifoam series address foaming issues in polymer dispersions and adhesive formulations, enhancing production speeds and ensuring defect-free applications. Evonik's expansive portfolio extends beyond defoamers to include wetting agents and dispersing agents. Our TEGOPREN® 5840 non-ionic polyether siloxane is celebrated for its super spreading ability and exceptional reduction of surface tension, making it invaluable for applications requiring rapid coverage of hydrophobic surfaces, is also compliant with food contact regulations. Moreover, SURFYNOL® AS 5080 stands out in our portfolio for water-based adhesives, improving wetting, reducing foaming, and modifying rheological behavior to enhance adhesive performance.

Our Ancamine® and Ancamide® curing agents enhance adhesive bonding with superior strength and flexibility and are suitable for both one-component (1K) and two-component (2K) systems. Products such as Ancamine® 2914UF and Ancamide® 2832 offer ultra-fast curing, allowing a quick return to service to increase productivity, while providing robust protection and aesthetic finishes in structural adhesives. The flexible polyamide curing agent Ancamide® 910, is specifically designed for the automotive industry, enabling strong adhesion between dissimilar materials ideal for lightweight electric vehicles. In automotive interiors, our tailor-made DYNACOLL® adhesives meet the challenges of new material bonding, balancing performance with ecological and economic considerations.

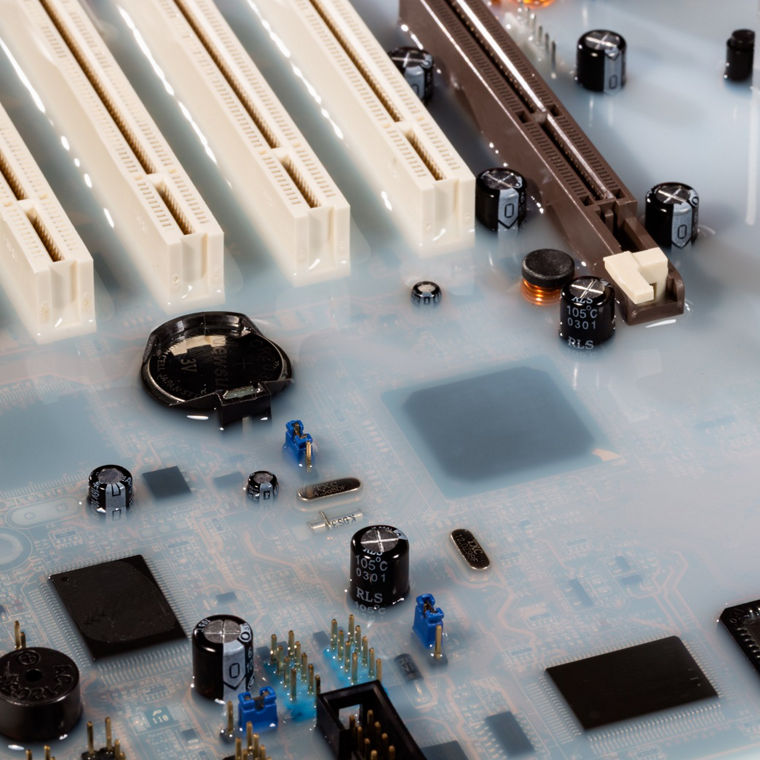

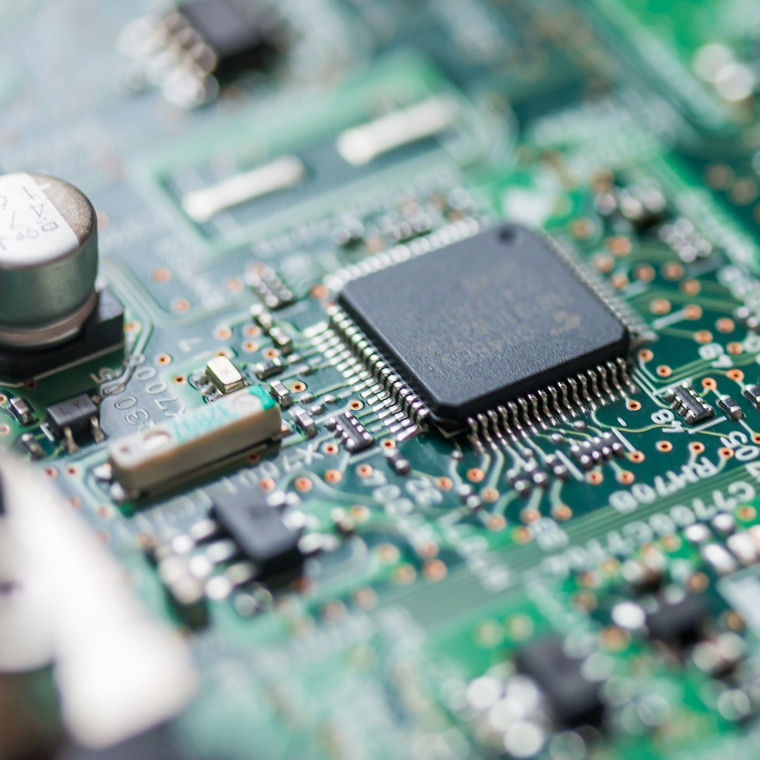

Evonik is committed to innovation and sustainability, providing a portfolio that meets the evolving needs of the industry. Our VESTOPLAST® grades exhibit excellent reactivity, UV stability, and strong adhesion making them ideal for various applications in automotive, construction, and electronics industries like solar panels. The Dynasylan® products elevate mechanical strength, chemical durability, material compatibility, and water-repellent properties. Our extensive selection features eco-conscious solutions, boasting minimal to zero VOC emissions, without compromising quality.

Other solutions like our VESTAMELT® copolyamide powders, are ideal for improving industrial bonding applications especially when working with steel and fiberglass or metal to metal. While products from our DYNAPOL® polyesters, POLYVEST® and DEGACRYL® ranges, ensure high performance and compliance with environmental standards in multiple applications. The characteristic microstructure of POLYVEST® products provide excellent reactivity and are widely used in automotive, construction, and electronics applications. While DEGACRYL® products represent our expertise in specialty acrylics, offering a broad range of methacrylic products for coatings, adhesives, medical, and ceramics applications, tailored for industries like food packaging and medical.

Our Catylen® S series based on magnesium ethanolate comes in various morphologies and is instrumental in optimizing catalyst performance. The Octolyst® base metal catalysts utilize active components from Group VIII metals and optionally copper, deliver high hydrogenation activity. Lastly, our Noblyst® brand of precious metal fixed bed catalysts, developed over three decades, exemplify our dedication to quality and innovation in catalyst technology and are utilized in vital industrial applications.

As a trusted global supplier, we support our customers with technical service capabilities, offering ongoing guidance, versatile testing equipment, and tailor-made formulations. Our mission is to deliver high-performance products and sustainable solutions, creating long-term value for our partners in the Adhesives and Sealants industry.

Additional markets we serve

- No matching location found

- Error when loading the data. Please try again later.