Enhancing efficiency and optimizing the hydrocarbon lifecycle are of critical importance in the the oil, gas and petrochemicals industry. As a leading specialty chemicals company, Evonik uses advanced chemistries to unlock reservoir potential, ensure asset longevity, and boost production capabilities.

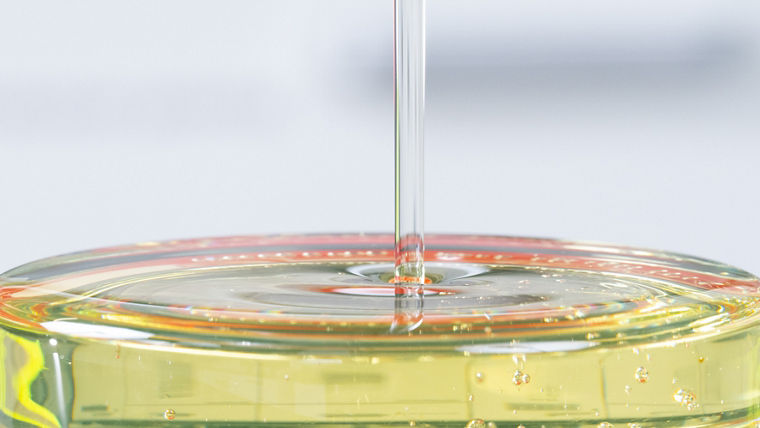

As part of our Care Solutions business, we supply methacrylates and methacrylamides to a broad range of sub-markets. These chemicals are essential for trouble-free operations in drilling, stimulation, production, and midstream sectors, including enhance oil recovery (EOR) and infrastructure. VISIOMER® specialty methacrylates, for example, are formulated to enhance oil recovery with a strong focus on chemical flooding, pushing the boundaries of existing recovery methods. As polymers, they are emerging as vital additives in applications such as fluid loss agents and friction-reducing polymers for stimulation fluids, addressing the specific challenges of high salinity and high-temperature reservoirs.

Rheology modifiers and viscosifiers based on aminofunctional methacrylates and ether methacrylates exceed expectations in modifying the rheological properties of substances, ensuring stability and processability, which are critical during extraction, transportation, and refining processes. Meanwhile, hydrate inhibitors and shale control applications protect the integrity and continuity of operations, mitigating risks that can lead to costly downtime.

Evonik's oil and gas surfactants demonstrate a commitment to environmental protection without compromising performance. With biodegradable technologies, they facilitate flowback, minimize water formation damage, and, when combined with corrosion inhibitors, provide protection under the most severe corrosion conditions. In hydraulic fracturing, our peracetic acid solutions such as PERACLEAN® serve as effective biocides, contributing to the safety and environmental aspects of hydraulic fracturing.

SEPURAN® hollow fiber membranes are the epitome of efficiency in gas separation, whether in biogas upgrading or nitrogen nitrogen generation. Customizable to specific applications, these high-performance polymers promote energy conservation and serve as the foundation for sustainable practices in gas processing.

In demanding situations where pressure and temperature challenge material integrity, VESTAKEEP® PEEK polymers offer unrivaled resilience and performance, whether in deep-sea drilling or under high pressure, high temperature (HPHT) environments. Simultaneously, VESTAMID® NRG for gas applications takes innovation beyond conventional materials such as steel, providing durable solutions in gas piping up to 18 bar.

Catalyst services encompass a full spectrum from pre-activation to rejuvenation, backed by our proprietary Excel technology. Ideal for sulfur recovery and hydroprocessing, our catalyst solutions such as Maxcel™ contribute to process optimization and environmental compliance.

Our product range extends to production, with chemistries such as VARONIC® for acid gas removal, DEGAPAS® anti-scalants and VISCOPLEX® for cold flow improvement. These, along with our PERACLEAN® biocides and VARIQUAT® cleaning agents, encapsulate a holistic approach to maintaining robust and clean operations.

Evonik's dedication to innovation in the oil, gas and petrochemicals industries underscores our commitment to providing solutions that not only enhance performance but also respect the environment — a vital driving force shaping the future of the energy sector

Global Presence

- No matching location found

- Error when loading the data. Please try again later.