Forward-Looking Solutions for Strong Adhesion

Benefits at a Glance

- Excellent adhesion properties – Even after rigorous corrosion tests.

- High stability – Compatible with a wide range of coatings.

- Easy integration – Seamlessly incorporated into existing formulations.

Adhesion and Corrosion Protection in DTM Coatings

Direct-to-metal (DTM) coatings often rely on adhesion promoters to achieve optimal adhesion and corrosion protection. Depending on the type of paint, specific silanes can greatly enhance performance.

For instance, while Dynasylan® GLYMO is widely used for various applications, it may not always deliver the desired results for adhesion and corrosion protection. In such cases, other silanes from Evonik's portfolio provide significantly better performance.

Car Repair Market

In the car repair industry, primers must meet the following key requirements:

Evonik's silanes, such as Dynasylan® 2101 and VPS 7163, play a crucial role in meeting these requirements, especially in improving adhesion and corrosion protection on different metals.

VPS 7163: Advanced Adhesion and Crosslinking

VPS 7163 is a versatile adhesion promoter and crosslinker suitable for one- and two-component polyurethane (PU) and acrylate coatings. Its unique structure enables additional crosslinking, leading to enhanced corrosion protection. This improvement is evident not only compared to coatings without silanes but also when benchmarked against other silanes.

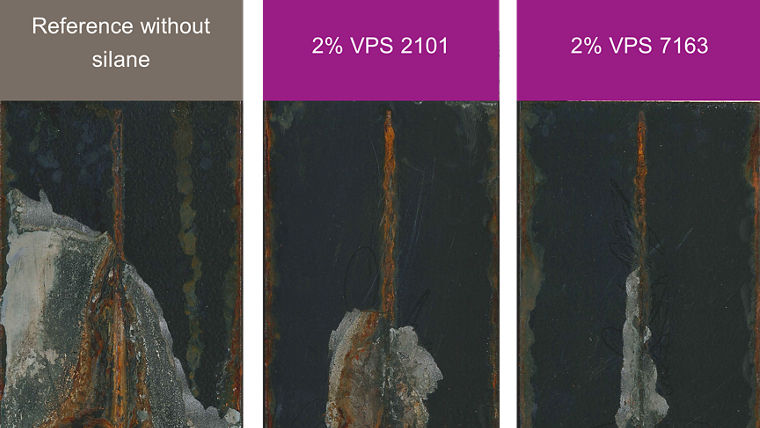

Dynasylan® 2101: Superior Corrosion Protection on Galvanized Steel

Dynasylan® 2101, a ureidosilane, offers exceptional adhesion on substrates like glass and galvanized steel (HDG). It significantly improves moisture and corrosion resistance in coatings. Unlike aminosilanes, its unique structure ensures compatibility with a wide range of coatings while minimizing any negative impact on stability.

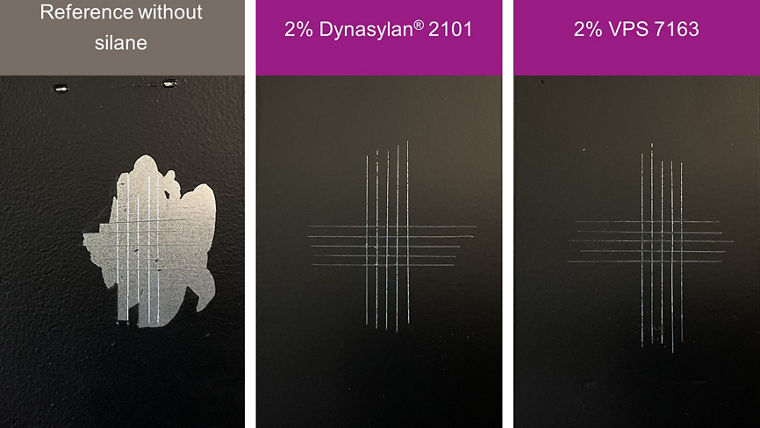

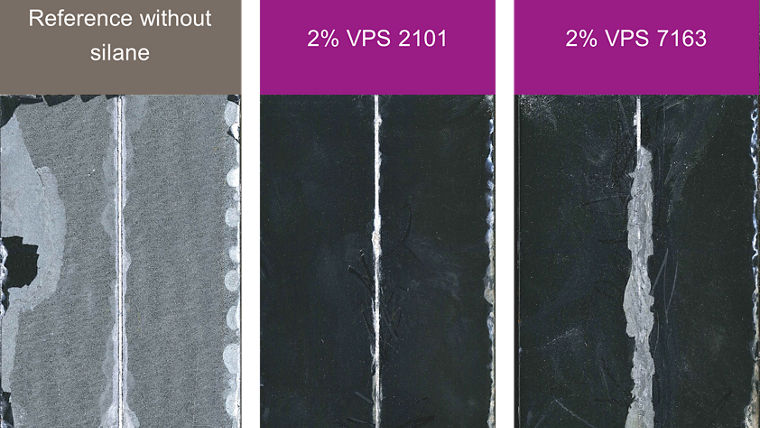

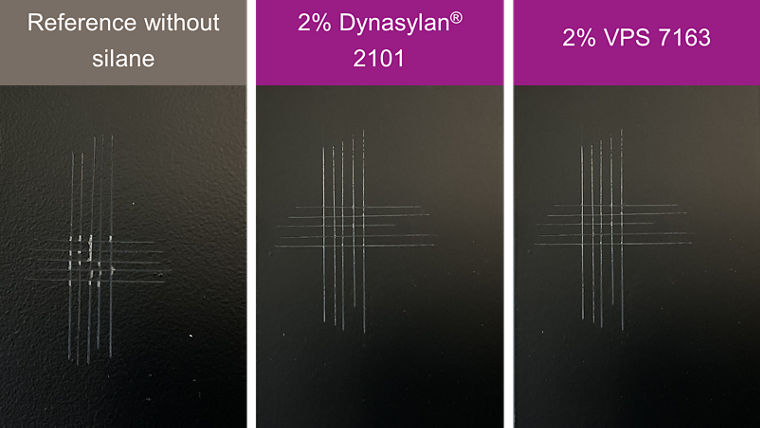

Proven Performance: Adhesion and Corrosion Protection

One of the major challenges for two-component PU coatings is maintaining adhesion on metals after salt spray tests. To evaluate performance, a commercially available two-component PU car repair coating was tested:

- Silanes Added: 2% silanes were added to Component A, though addition to the isocyanate hardener (Component B) may also improve stability.

- Film Thickness: 100–150 µm.

- Flash-Off Time: 15 minutes at room temperature.

- Curing Conditions: 20 minutes at 60°C.

- Plate Aging Before Testing: 7 days at room temperature.

The results demonstrated excellent adhesion and very good corrosion protection, validating the effectiveness of VPS 7163 and Dynasylan® 2101 in demanding applications.