T stands for texture: Re-innovate your textured powder coatings with TEGO® Powder Aid T-series

Benefits at a Glance

- Alternatives to PTFE for texturing show promising results

- Enhance adhesion properties for labeling purposes

- Reach out to our expert to OUTPERFORMULATE your formulations

In comparison to non-textured coatings, these finishes offer various additional benefits. For the end consumer this is e.g. a silky surface with smooth haptics and high resistance to surface scratches on otherwise cold and low-cost appearing plastic substrates. Operators in paint shops experience added value through less significance of not perfectly pretreated parts or welding marks and paint manufacturers have a mitigated risk of rejected batches due to lower visibility of small surface imperfections such as craters or specks. Depending on the nature of the substrate, the durability and resistance expectation of the coating towards environmental and mechanical impact, as well as the desired texture, various methods and chemistries can be applied to achieve the optimal result.

Texturing with micronized PTFE

One of the options to create fine surface textures on powder coatings is to formulate them with micronized PTFE (Polytetrafluoroethylene) texturing additives. While providing a low gloss, smooth surface haptics and an evenly distributed texture, such coatings are relatively robust, even under inconsistent application and/or production parameters. In direct-to-metal applications their usage allows for example window and door frames to withstand abrasion and reduce light reflections or furniture components to be extremely scratch resistant. At the same time they show a similar texture and gloss as surface coated medium-density fiberboard (MDF) panels and allow for multiple design options.

PTFE and PFAS-alternatives for texturing

PTFE, as part of the group of so-called Per- and Polyfluoroalkyl Substances (PFAS) which lately gained a lot of attention due to their ecotoxicity, does not seem to have a bright future. As of June 2020, the European Chemicals Agency (ECHA) widely restricted the use and banned products that contain more of 25 parts per billion (ppb) of Perfluorooctanoic acid (PFOA), the main raw material to manufacture PTFE texturing agents, so coating manufacturers all over the world will need to look into alternatives (2).

Within Evonik Coating Additives Division, this industry trend sparked a number of innovation projects to help customers finding suitable alternatives to PFAS. Latest development results indicate that currently there is no 1:1 replacement solution available, but in terms of performance silica-based innovation products already demonstrates promising results.

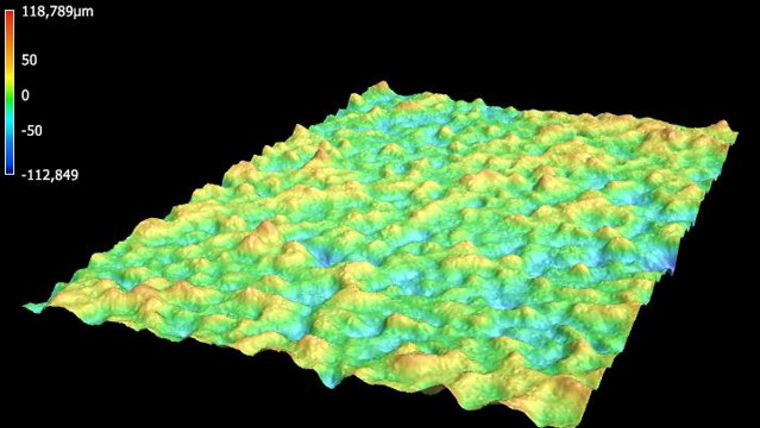

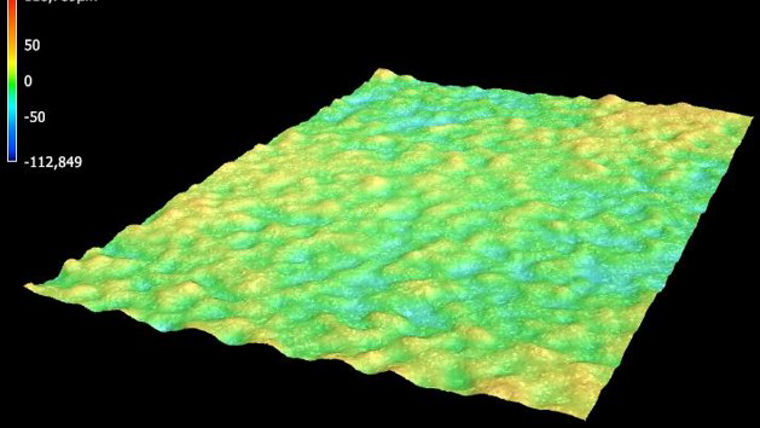

Comparing the surface texture on a microscopic level, one innovative development product (Figure 1) already shows a very similar surface roughness profile as a current market standard PTFE containing product (Figure 2). In addition to that, the development product shows much less significant influence on reducing the surface energy of the cured film, resulting in better adhesion properties of attached product labels.

As the development for innovative and sustainable products is a continuous endeavor, feel free to reach out any time and address your formulation needs. The team is more than happy to OUTPERFORMULATE your top products together with you.

(1) https://www.fortunebusinessinsights.com/texture-paints-market-108978

(2) European Chemicals Agency https://echa.europa.eu/-/echa-weekly-17-june-2020