AMINONIR® is Evonik’s analytical service for feeds and feed raw materials based on near infrared (NIR) technology. It offers reliable nutritional analysis in minimal time – even with unground raw materials.

Typical Applications

Benefits at a glance

- Covers the widest number of feed ingredients used by the feed industry

- Provides up-to-date, timely and reliable knowledge of fluctuating feed ingredient quality

- Helps reduce the proportion of costly ingredients, while boosting feed conversion ratios

- Provides customers with access to continuous support from industry experts

- More accurate feed analysis benefits livestock health and helps lower nitrogen emissions

- Easy sample preparation

Markets & Applications

Optimizing feed formulations based on timely and precise nutritional analyses

For data-driven decision-making

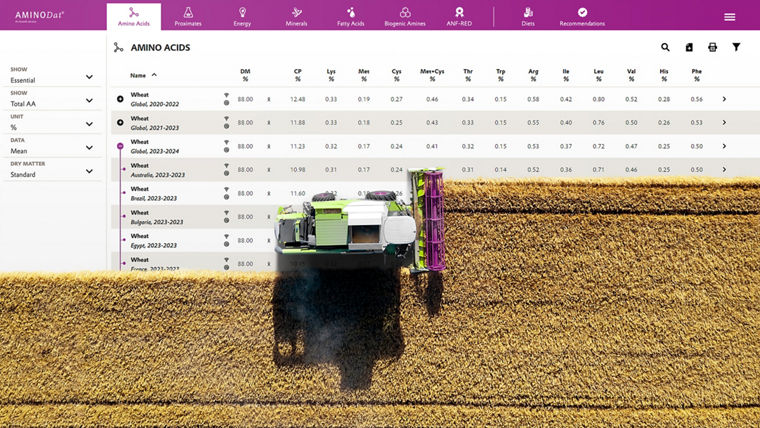

Precise analysis of raw materials is essential for high feed quality. AMINONIR® utilizes cutting-edge near-infrared (NIR) spectrometry to analyze the nutritional composition of more than 60 feed ingredients and finished feeds. This innovative approach not only provides rapid results but also ensures high accuracy, allowing users to make informed decisions that enhance the health and productivity of livestock.

Samples can be processed through onsite NIR equipment (Bruker or FOSS), or alternatively sent to Evonik labs. It works for ground and unground ingredients. The advantages of AMINONIR® are easy sample preparation, speed and low operating costs, enabling extensive screening programs at moderate cost.

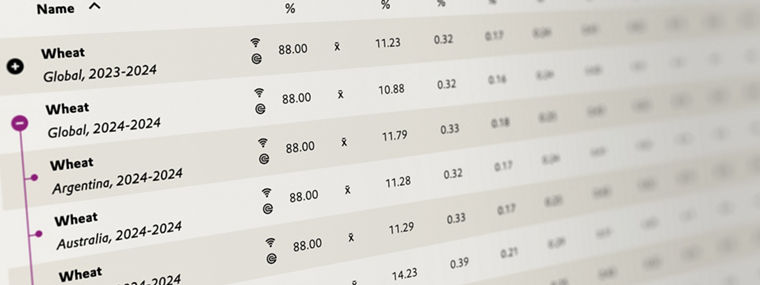

Overview of available calibrations

- Pig Feeds

- Poultry Feeds

- Fish Feeds

- Shrimp Feeds

- Ruminant Feeds

- Cereals

- Cereal byproducts

- Brewing & distilling

- Oil seeds & meals

- Pulses

- Animal byproducts

- Milk byproducts

- Forages

- Fats & oils

- Proximates

- Energy

- Amino acids

- Fatty acids

- Anti-nutritional factors

- Processing parameters

- Digestible and resistant starch

- Fiber fractions

- Fat quality parameters

- CNCPS

Get results in four easy steps

Step 1: Fill the cup

AMINONIR® supports a huge variety of raw materials and finished feeds that can be scanned in order to receive detailed information about their nutritional values.

Step 2: Scan the sample

Place the sample in the NIR cup. Evonik’s technology can analyze the sample as it is (unground or ground). For AMINONIR® services you can use NIR spectroscopy devices from FOSS and BRUKER.

Step 3: Upload your data

Uploading is as easy as scanning. Within seconds, you can transfer the data by web browser or via the AMINONIR® Advanced web service interface. There’s no need to select any material types or input complicated data.

Step 4: Get your report

You’ll find everything you need to know about your raw materials or finished feeds in one detailed report.

Determining the nutritional value of soybean products

Amid rising raw material and energy costs, efficiency has never been more important. By utilizing tools like Evonik's AMINONIR® service, feed producers can quickly and reliably evaluate the nutritional value of soybean products and reduce variation in animal diets, ultimately improving performance and increasing feed efficiency.

The digital solution for science-based feed optimization

In NIR spectrometry, invisible near infrared light is beamed to a sample, causing molecules in the sample to vibrate. This interaction with the molecules consumes energy by absorbing elements of the introduced light. In the case of liquid samples, residual light passes through the material, while solid samples reflect the light. This light is measured with a detector and gives a spectrum.

The spectral information is further used and evaluated, for example to identify unknown samples (fingerprinting) or to estimate its nutritional composition via the application of NIR calibrations.

FAQs

AMINONIR® supports the operations of feed millers, soybean processors, and producers of corn DDGS (distiller's dried grains with solubles), rapeseed, mustard meal, fish meal and animal byproduct meal.

AMINONIR® supports more than 60 raw materials and finished feeds:

|

|

|

Instruments from these providers are capable of performing analyses of raw materials and finished feeds:

|

|

AMINONIR® Plugin is the Evonik web service interface that allows a fully automated and seamless network integration and technical data exchange in the background, including spectra uploads and results transfer from and to Foss Mosaic and Bruker OPUS.

AMINONIR® Advanced 3.1 allows customers to upload spectra files via web browser in seconds. Processing occurs automatically: There’s typically no need to select material types or input complicated data, and there’s no chance for operator mistakes. Analytical Data Advanced 3.1 is a web-based tool that provides results as a downloadable PDF, XLS, CSV, or XML file. Users can also schedule automatic email delivery of the files when new data is available.

What makes AMINONIR® services stand out is Evonik’s experience in calibration development. In NIR calibration development, spectra of many typical samples of one material are combined with the corresponding values of an analytical reference method. The final calibration describes the correlation between the set of spectra and the reference values. By applying that correlation to spectra of further unknown samples, all calibrated parameters can be mathematically predicted.

The quality of reference analysis is critical to calibration accuracy. For this reason, reference labratories must be inspected on a regular basis. Evonik’s reference lab – AMINOLab® – is a network of three wet-chemistry laboratories based in Germany, China and Singapore. Their accuracy and precision is monitored via regular independent ring tests as well as by internal control samples.

Connect with our experts

Whether you run a feed mill or livestock operation, produce meat, dairy, or eggs — Evonik is here to support you. Wherever you're located and whatever your needs, our Evonik Animal Nutrition specialists are ready to assist you.

The content of this webpage is for the information and assistance of Evonik’s customers and is not applicable to products marketed or sold in the United States.

Evonik markets its products in compliance with applicable local laws, but it is the user’s responsibility to ensure that the use of and any claims made for this product comply with all relevant requirements.