Microchip Manufacturers Trust in the Versatility of Hydrogen Peroxide

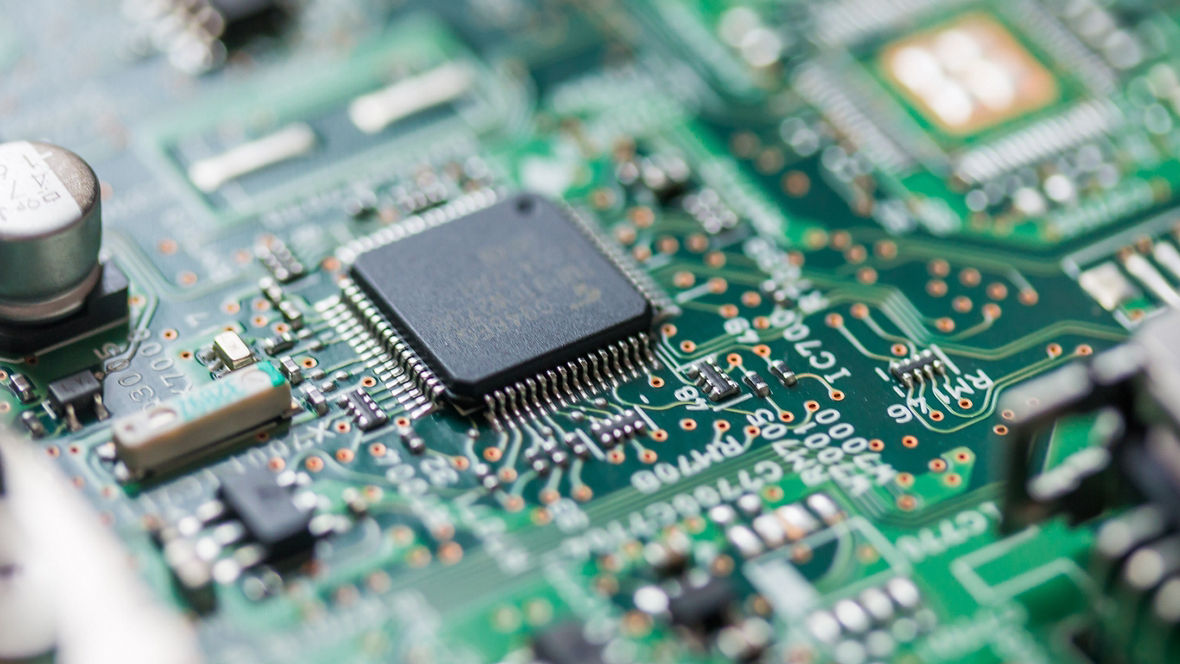

Semiconductors are essential for many of today's key technologies, processing electronic signals and transmitting information. They are crucial for items like automotive sensors, smartphones, servers, medical devices, robots, solar power, and wind turbines.

Among the chemicals used in microchip manufacturing, hydrogen peroxide (H₂O₂) ranks as the second most utilized after ultra-pure water in wafer fabrication. H₂O₂ is considered a green chemical, because it decomposes after use into harmless water and oxygen. In semiconductor microchip manufacturing, it removes various contaminants across all wafer layers, producing high-yield, functional microchips used in a wide range of electronic devices today.

A closer look reveals that hydrogen peroxide is also a highly versatile chemical. Even outside the chip industry, H₂O₂ plays a role in recycling the valuable metals in batteries and manufacturing solar cells.

Let's Take a Closer Look. What Exactly does H₂O₂ Do in Semiconductor Manufacturing?

Hydrogen peroxide fulfills several functions. When combined with certain other chemistries, H₂O₂ cleans wafer surfaces and effectively removes various types of surface contaminants and residues from the wafer. It also acts as an oxidizer to assist in removing metal layers on the wafer.

The semiconductor industry has historically depended on hydrogen peroxide as a cleaning agent. Any contamination on a microchip can impair its functionality. High-purity H₂O₂ significantly reduces defect levels on wafers, enhancing overall yield by the time the wafers reach the end of the production line. This translates to a higher number of functioning microchips. Given that any form of contamination can render a microchip inoperable, the cleanliness conditions within manufacturing facilities must be more stringent than those of a hospital operating room.

Hydrogen peroxide can also be used to recycle rare metals…

The strengths of H₂O₂ are in demand beyond semiconductor manufacturing—particularly in the circular economy. Hydrogen peroxide supports the recovery of valuable metals from lithium-ion batteries. It shortens the recycling process and makes it more efficient. In particular, lithium, cobalt, and nickel are returned to the production cycle this way.

… and providing nanoparticles for solar modules

When it comes to preparing silicon-based nanoparticles for the solar industry, that too is a task for H₂O₂. By dissolving the nanoparticles from crystalline silicon, it performs the preliminary work needed to later apply them to solar modules. There, the nanoparticles enable the conversion of solar energy into usable power. All these applications make hydrogen peroxide a forward-looking chemical.