Ready for Fast, Functional, and Future-Ready Processes?

At Evonik, we understand the pressure to innovate quickly, scale reliably, and meet the highest standards of quality and sustainability in pharmaceutical development. That’s why our advanced processes are designed to help you accelerate custom API and intermediate synthesis—from early-stage screening to commercial production.

Whether you're:

- Launching a new drug candidate

- Optimizing an existing synthesis route

- Navigating complex regulatory landscapes

- Seeking greener, more efficient manufacturing solutions

What are Advanced Processes?

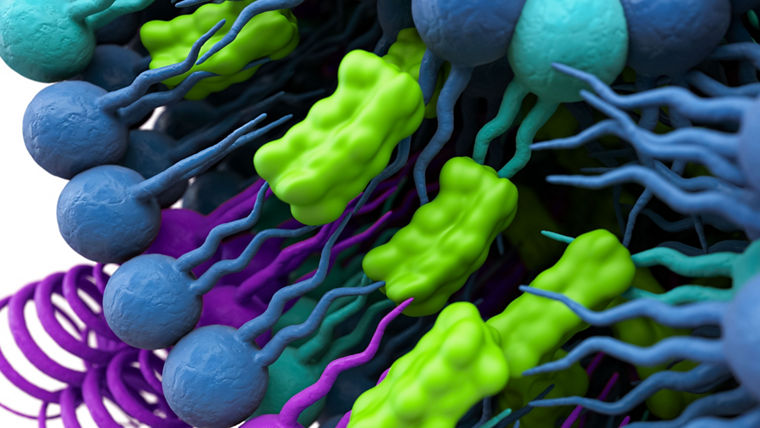

Advanced processes refer to the integration of cutting-edge technologies and methodologies that elevate industrial operations—especially in highly regulated and innovation-driven sectors like biotech, chemical manufacturing, and pharmaceuticals.

These processes go beyond traditional improvements by incorporating:

- Digital tools for real-time control

- Automation for consistent quality

- AI-driven systems for intelligent decision-making

Evonik applies the full scope of digital and AI-supported screening, development, and processing methodologies to enable more efficient synthesis of active pharmaceutical ingredients (APIs) and intermediates. This accelerates drug development timelines and helps bring new therapies to market faster.

Driving Innovation and Sustainability in API Manufacturing Through AI and Digital Technologies

By integrating advanced technologies into our processes, Evonik empowers customers to innovate faster, operate smarter, and grow more sustainably. Our approach is designed to support your goals—whether you're scaling up a new synthesis route, optimizing production efficiency, or meeting stringent regulatory requirements.

We help you achieve:

- Continuous Process Improvement: Through automation, real-time analytics, and AI-driven optimization, we enable faster iteration and smarter decision-making across development and manufacturing.

- Regulatory Compliance: Our advanced process control and analytical technologies ensure consistent quality and traceability, helping you meet global regulatory standards with confidence.

- Long-Term Environmental Responsibility: By minimizing waste, improving resource efficiency, and enabling greener chemistry, our solutions support your sustainability targets and reduce environmental impact.

Partnering with Evonik means gaining access to a future-ready infrastructure that transforms complexity into competitive advantage.

Key Tools and Platforms Used in Advanced Processes

Evonik’s advanced process capabilities are powered by a suite of tools and platforms:

- Bayesian Optimization Platform: Uses machine learning to accelerate experimental design and maximize performance.

- Custom Reactor Design Tools: Combined with SLM metal 3D printing for scalable, complex reactor architectures.

- CFD & Multi-Physics Simulations: Model and optimize reaction environments for ideal mixing, heat transfer, and mass transport.

- Automated Laboratory Platform: Enables high-throughput, reproducible screening with minimal manual intervention.

- Process Analytical Technology (PAT): Provides robust monitoring and real-time data analysis for quality and compliance.

The Benefits of Advanced Processes

Applying digital and AI-supported technologies has a number of advantages in API synthesis.

- Shortens development cycles

- Speeds up time-to-market

- Enables rapid response to market demands

- Enhances product quality and consistency

- Optimizes resource utilization

- Minimizes waste and environmental impact

- Supports right-first-time technology transfer

- Reduces risk in commercial production

- Ensures predictable outcomes and cost savings

Case Studies

In this case, Evonik used advanced process technologies to dramatically improve chemical process development through a fully integrated, closed-loop optimization system.

How did this work?

- AI-Driven Autonomous Control

The system used artificial intelligence to automatically adjust reaction conditions in real time, ensuring optimal performance without manual intervention.

- Infrared (IR) Monitoring

IR sensors continuously track the progress of the chemical reaction, providing instant feedback that helps fine-tune the process for maximum efficiency and consistency.

- 3D-Printed Reactor Components

Custom-designed reactor parts, created using advanced 3D printing, improve heat and mass transfer—making the system highly adaptable and responsive to changing conditions.

What was the impact?

- 50–100× Faster Experimentation

Thanks to the seamless coordination of AI, real-time monitoring, and flexible reactor design, development cycles were accelerated dramatically—cutting timelines and boosting productivity.

In this case study, Evonik demonstrates how advanced processing can revolutionize industrial workflows through closed-loop optimization:

- AI-Driven Autonomous Control

Enables real-time decision-making and adaptive process adjustments. - Infrared (IR) Monitoring

Provides continuous data on reaction progress for immediate optimization. - 3D-Printed Reactor Components

Designed for superior heat and mass transfer, allowing rapid and flexible modifications. - Accelerated Experimentation

Achieved 50–100× faster development cycles, significantly reducing timelines.

This integrated approach showcases how digital and AI technologies can deliver unprecedented speed, precision, and sustainability in process optimization—offering a clear path toward innovation in biotech, chemical, and pharmaceutical manufacturing.

Advanced Processes vs. Advanced Processing

While the terms are closely related, they serve distinct purposes:

- Advanced Processes: Specific, sophisticated workflows or procedures enabled by modern technologies—such as novel synthesis, purification, or formulation techniques.

- Advanced Processing: The broader transformation of production environments through digital and automated systems.

Get Support from Our Experts Every Step of the Way

With deep technical expertise, specialized digital platforms, and a commitment to collaboration, our experts are ready to help you turn complexity into competitive advantage.

ANY QUESTIONS LEFT? JUST CONTACT US.

"Exploring options for the development and manufacture of your cGMP small molecule drug substance or associated intermediates? Reach out and we'll help you make well informed choices as Evonik aims at getting clients practical solutions faster and easier."

Eric Neuffer

Head of Drug Substance Sales