Shaping the future of medical device innovation with next-generation biomaterials

Evonik offers a broad portfolio of biomaterials for medical devices that meet the highest standards of biocompatibility, biostability, and performance. Our biomaterials support innovation in medical devices, from short-term to long-term implantable devices, while our bioresorbable medical polymers enable controlled degradation, opening further possibilities for medical device applications.

The role of biomaterials in medical devices

Biomaterials are the foundation of safe and effective medical devices. These materials must interact with the human body without causing adverse reactions, making biocompatibility a critical requirement. Evonik’s biomaterials are engineered to be non-toxic, non-immunogenic, and compliant with stringent regulatory standards. Equally important is biostability—the ability of a material to maintain its integrity and functionality over time within the body.

Evonik’s expertise in advanced biomaterials

With decades of experience in polymer science and medical-grade material development, Evonik is a trusted partner to the global medical device industry. We offer a comprehensive range of high-performance biomaterials, including RESOMER®, VESTAKEEP®, and VECOLLAN®, each tailored to specific medical applications. Our team supports customers with customization, regulatory guidance, and global technical support, helping accelerate product development from concept to market.

Materials intended for short-term body contact—typically up to 30 days—must meet specific regulatory and performance criteria. Evonik offers a range of materials for applications such as catheters, wound care products, and surgical tools. Our care-grade polymers, including VESTAKEEP®, TROGAMID®, and VESTAMID®, are tailored for short-term use. For wound care and medical aesthetics, epicite® provides advanced healing properties, while ENDEXO® surface modification technology enhances the hemocompatibility of medical devices, reducing thrombosis and biofouling.

| Products | Class of material | Property | Processibiity | Application area |

|---|---|---|---|---|

| Endexo® | Additive technology | Short-term up to long-term body contact | ||

| Epicite® | Biosynthetic cellulose | Short-term body contact | ||

| POLYMER VS | Addition curing silicones | Short-term body contact (Wound care, Explants, etc.) |

| |

| ROHACELL® | Polymethacrylimide (PMI) | Short-term body contact | ||

| TROGAMID® CARE | Transparent polyamides (PA) | Short-term body contact | ||

| VESTAKEEP® Care | Polyether ether ketone polymer ( PEEK) | Short-term body contact |

| |

| VESTAMID® Care ML | Polyamide 12 polymer (PA12) | Short-term body contact | ||

| VESTAMID® Care ME | Polyamide 12 elastomers (PEBA) | Short-term body contact | ||

| VESTENAMER® | Trans-polyoctenamer rubber (TOR) | Short-term body contact | ||

| VESTODUR® | Polybutylene terephthalate (PBT) | Short-term body contact | ||

| VISIOMER® | Specialty Methacrylate Monomers | Short-term body contact Long-term body contact |

|

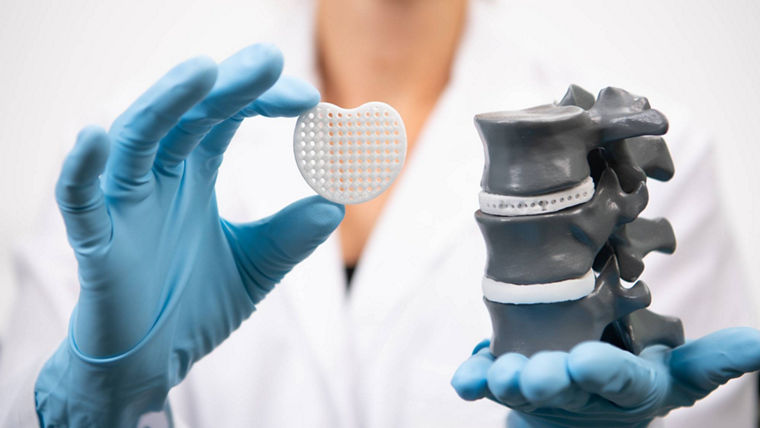

Devices that remain in the body for more than 30 days require materials with exceptional biostability, mechanical strength, and safety. Evonik’s portfolio includes VESTAKEEP®, DEGACRYL®, and DEGAPLAST®, which perform reliably in long-term implantable applications such as orthopedic devices, stents, and spinal implants. These materials are tested for durability and resistance to physiological stress, ensuring consistent performance over the life of the device.

| Products | Class of material | Property | Processibiity | Application area |

|---|---|---|---|---|

| biocellic® | Biosynthetic cellulose | Long-term body contact | ||

| DEGACRYL® | Polymethyl methacrylate (PMMA) | Long-term body contact | ||

| DEGAPLAST® | Acrylic based resins | Long-term body contact | ||

| NANOCRYL® D | Nanosilica concentrates for acrylic resins | Long-term body contact (Artifical teeth) |

| |

| Polyether ether ketone polymer ( PEEK) | Long-term body contact |

| ||

| VISIOMER® | Specialty Methacrylate Monomers | Short-term body contact Long-term body contact |

|

Driving innovation through collaboration and technology

Innovation is at the heart of Evonik’s approach to biomaterials. We develop next-generation biomaterials to meet the evolving needs of the medical device industry and collaborate closely with manufacturers on solutions that address specific clinical challenges. From early-stage concept development to regulatory support, we offer a full spectrum of services. Our custom material solutions are designed to accelerate time-to-market while ensuring compliance and patient safety.

Process technologies: Specialized support for medical device manufacturers

At Evonik, we don’t just supply biomaterials—we partner with medical device innovators to solve complex processing challenges through customization and collaboration. Our advanced process technologies, from precision injection molding to textile engineering, are designed to unlock the full potential of next-generation biomaterials. We can prototype, develop, and scale customized biomaterials. Our approach not only accelerates the development cycle but also ensures that patient safety remains a top priority throughout the design and manufacturing process.

ANY QUESTIONS LEFT? JUST CONTACT US.

"Our global team of experts is ready to support you with all questions around our broad portfolio of high performance biomaterials for medical devices. Contact us to profit from more than 30 years of application know-how in the field of medical devices and find your individual solution!"

Mandy Roovers-Wiermans

Business Development Manager Medical Device Solutions