We Turn Your Formulation Into Sustainable OUTPERFORMULATIONS!

At Evonik Coating Additives, we understand the challenges formulators face in balancing performance, regulatory demands, and environmental responsibility. That’s why we’re committed to turn your formulation into sustainable outperformulations.

Our advanced additive technologies are designed to reduce environmental impact while enhancing functionality - whether it’s lowering VOCs, improving durability, or enabling waterborne systems. With a deep focus on lifecycle thinking and resource efficiency, we provide the tools and expertise you need to create coatings that meet today’s sustainability standards and tomorrow’s expectations.

Together, we can shape a more sustainable future - one formulation at a time.

This website embeds YouTube videos. To load the YouTube player and view the video at this point, please first agree to the transfer of your personal data to Google. For more information, please see Evonik Privacy Policy

Our Strategy - How to Add Value to Sustainable Solutions

We contribute to sustainable and circular value chains with two pillars: Next Gen Technologies and Next Gen Solutions.

Next Gen Technologies reduce our environmental emissions by sourcing more sustainable raw materials and using utilities more efficiently. Our milestones are SBTi approved.

Next Gen Solutions are products and solutions with clearly positive sustainability profile. They enable positive environmental impacts along the value chain compared to other established products and applications on the market. The contributions occur downstream of Evonik’s production process at customers or end users.

What sustainability looks like for Coating Additives and for our customers

Increasing sustainable value in coatings and inks to support our customers drives our solutions.

We are committed to the reduction of our scope 1, 2 and 3 emissions via more sustainable feedstocks, renewable energy and optimized processes.

Sustainable feedstocks: Together with Procurement and Supply Chain Management, we constantly screen the market for alternatives to fossil based raw materials. Our focus is to find and qualify less carbon intensive raw materials from biobased, recycled or CO2 based sources.

Renewable energy: We do see the switch to renewable electricity as the starting point for the decarbonization of our production processes. The process is supported by a step wise investment into electricity driven processes for steam and heat generation.

Process optimization: We create transparency via the monitoring of plant specific energy consumption as well as information from life cycle assessments of our products. Based on this information we identify potentials for more efficient production processes with the goal to reduce the specific and absolute energy consumption.

For more information visit:

Information about raw materials

We have identified six topics which we address with our Next Gen Solutions. Our portfolio steering and innovation management fully focuses on the development of solutions that deliver tangible effects for at least one of these topics.

Please find a detailed description of the attributes in the list below:

Safe Use

We constantly monitor regulatory trends in the chemical and relevant downstream industries. Based on this, we analyze our portfolio for current and upcoming risks. For each product with safety related risks, we carry out individual actions to reduce or replace hazardous components.

Labels/Compliance

Driven by legislation or independent organizations, there’s an increasing need for compliance of coatings to eco labels or regulatory standards. We analyze our existing portfolio for compliance and clearly communicate the compliance status of our products. We consider today´s and future compliance needs in our product development.

VOC Reduction

The negative impact of volatile organic compounds (VOC) to the environment is well known. As a consequence, the emission of VOCs from paints and coatings is strictly regulated in an increasing number of countries. We offer a broad portfolio which enables coating and ink companies to formulate low VOC formulations.

Production Efficiency

The formulation and application of paints, coatings and inks includes several time and energy consuming steps. We offer solutions to optimize and reduce your material and utility input, e.g. in the following situations:

- Pigment grinding and dispersion

- Substrate wetting and foam destruction in the application phase

- Room temperature instead of oven curing coatings

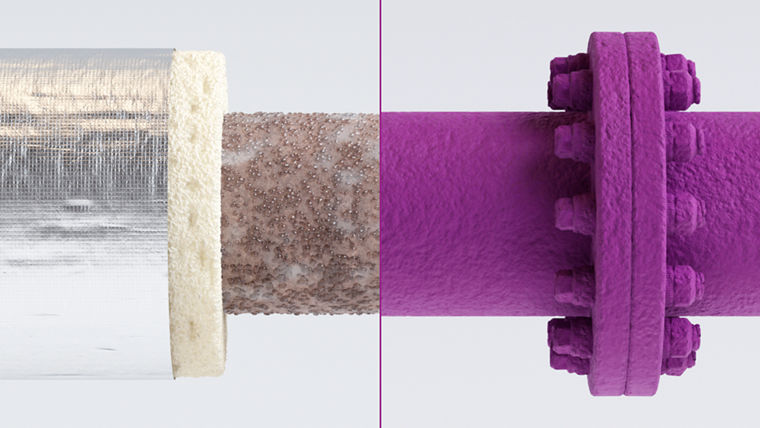

Durability

The function of paints and coatings in the use phase of coated articles is to provide appealing surfaces and to protect the substrate against various kinds of damages. We offer powerful solutions for durable coatings, such as:

- Corrosion resistance

- Scratch resistance

- Burnish Resistance

Circular Solutions

Current value streams are in most of the cases linear, resulting in the ongoing exploitation of natural resources and ever-increasing volumes of waste. Evonik pools its activities for circular solutions in the Circular Plastics Program. The Coating Additives Business Line is part of this activity. We focus on the development of circular solutions for paints, coatings and inks.

We have products for more sustainable coatings and inks!

At Evonik Coating Additives, we use different analyses for the measurability of sustainability:

Portfolio Sustainability Analysis (PSA): The PSA is a framework to evaluate the sustainability profile of our products and production processes. We use the PSA to capture increasing stakeholders’ expectations, turn socio environmental risks into business opportunities and foster our portfolio transformation. It is applicable to existing products & services as well as innovation projects. Products with a positive sustainability profile are outlined as Next Gen Solutions.

Life Cycle Assessment (LCA): LCA is a methodical analysis of the environmental impact of a product or service with the purpose of making sustainability quantifiable. Using life cycle assessment methods, key metrics such as carbon and water footprints are generated to show environmental impacts of our business activities.

For more information visit:

Keeping up with regulatory information is vital in our industry. When it comes to regulatory inquiries regarding our products, our global team of experts is available to provide the best possible customer support. Our expertise allows us to help customers meet all necessary regulatory requirements, thereby giving a boost to the development of new formulations.