Special solutions such as AEROXIDE® make lithium-ion batteries safer and more powerful. This could give electric mobility a further boost. In October 2025, Evonik commissioned its first plant for fumed aluminum oxide in Asia, which is the center of global battery production.

Many everyday technologies are possible only because of powerful energy storage systems. This is especially true of electric mobility, where numerous advancements in battery technologies over the past few decades have made electric cars increasingly competitive with conventional gasoline-powered vehicles. Most electric vehicles are powered by lithium-ion batteries. And although they have dominated the market for many years, their potential in terms of performance, range, and safety during use is far from exhausted.

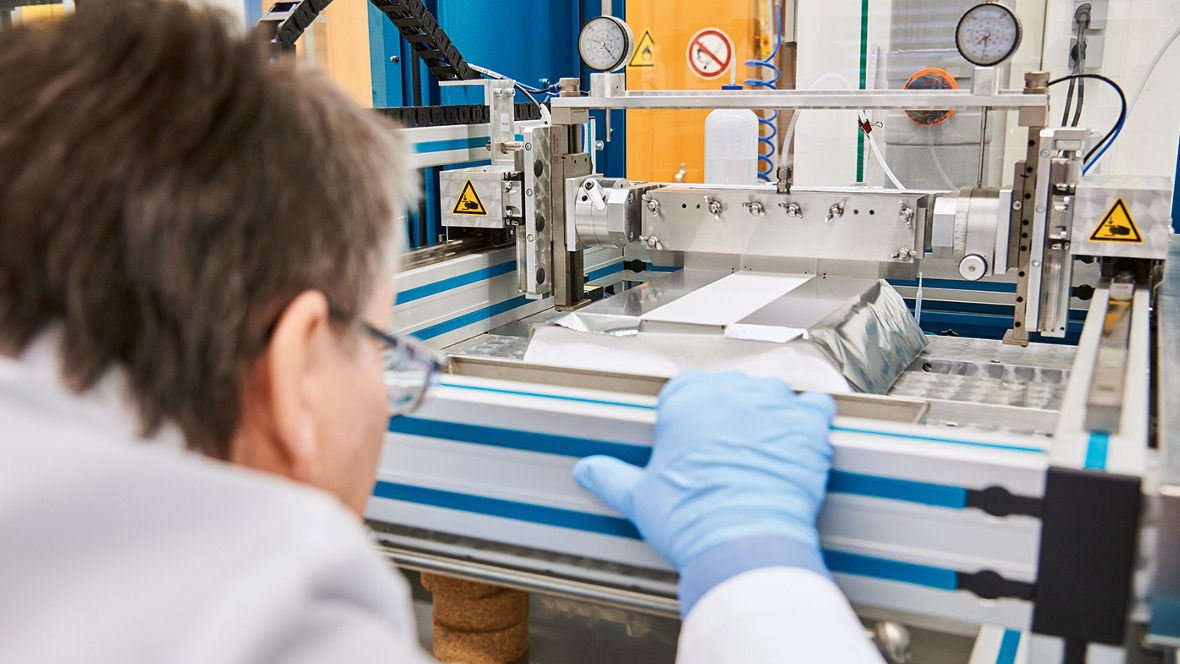

Evonik is addressing exactly this issue. As an established innovation partner of the battery industry, the company produces various AEROXIDE® brand performance additives for lithium-ion batteries.

AEROXIDE® PREVENTS SHORT CIRCUITS AND INCREASES CAPACITY

Lithium-ion batteries were launched on the market around 30 years ago. Since then, they have basically consisted of the same components: a separator between a cathode made of lithium mixed oxide and an anode usually made of graphite, both soaked in a liquid electrolyte solution. In this system, the separator acts as a kind of barrier that electrically isolates the two electrodes from each other. The problem is that the thin separator, which consists of a porous polymer, tends to shrink as soon as heat is generated in the battery cell. This increases the risk of a short circuit, followed in the worst case by thermal runaway of the entire battery.

An ultra-thin coating of AEROXIDE® on the separator prevents the shrinkage process and thus increases safety. AEROXIDE® coatings also protect the high-performance cathodes of lithium-ion batteries from premature degradation.

FIRST EVONIK PLANT FOR FUMED ALUMINUM OXIDE IN ASIA

Evonik serves the growing market for lithium-ion batteries with its products. In a joint study, RWTH Aachen University and the strategy consulting firm Roland Berger calculated that the global battery market will grow by 34 percent annually between 2020 and 2030. Asia, the center of global battery production, will benefit from this boom. Asia is home to numerous major manufacturers who have been decisively shaping the future of the industry for years.

In order to exploit the potential of this growing market, Evonik laid the foundation stone for its first plant for fumed aluminum oxide in Asia in Yokkaichi, Japan, in spring 2023, focusing on the production of special solutions for lithium-ion battery technologies. The facility was commissioned on schedule in October 2025. The specialty chemicals company has invested an eight-digit euro sum in the project, and the Japanese government supported the construction with funding.

SHORT DELIVERY ROUTES TO MANUFACTURERS OF LITHIUM-ION BATTERIES

Evonik has been operating the Yokkaichi site in a joint venture for more than 50 years. The plant started with the production of AEROSIL® brand silicas and gradually expanded its operations to include other products. “We’ve been producing top-quality fumed oxides in Yokkaichi for many decades,” says Goro Naito, President of Evonik Japan. “Now we are also using this expertise for the production of fumed aluminum oxides.” Evonik is now supplying the major battery manufacturers in China, Korea, and Japan with products such as AEROXIDE® more quickly and cost-effectively from Yokkaichi. “This will give a further boost to electric mobility in Asia,” says Naito.

The employees at the site have mastered numerous challenges in the course of the project. These included finding solutions to the problem of optimally integrating the new plant in the existing infrastructure of the location. Shogo Ichinozuka, an engineer in production technology, and his colleague Saefuludin are responsible for the production processes. “We also use parts of our existing fumed oxides plant to produce the aluminum oxides. The challenge here has been to optimally match the processes to one another and to continually improve them,” says Ichinozuka, who sees the expansion of production capacity in Yokkaichi as a great opportunity. “All of us are very proud to be operating the first Evonik plant of its kind in Asia. In this way, from our location we can help to lead mobility into a sustainable future.”

All of us are very proud to be operating the first Evonik plant of its kind in Asia. In this way, from our location we can help to lead mobility into a sustainable future

Shogo Ichinozuka, engineer, Yokkaichi