From scrap tires to new products

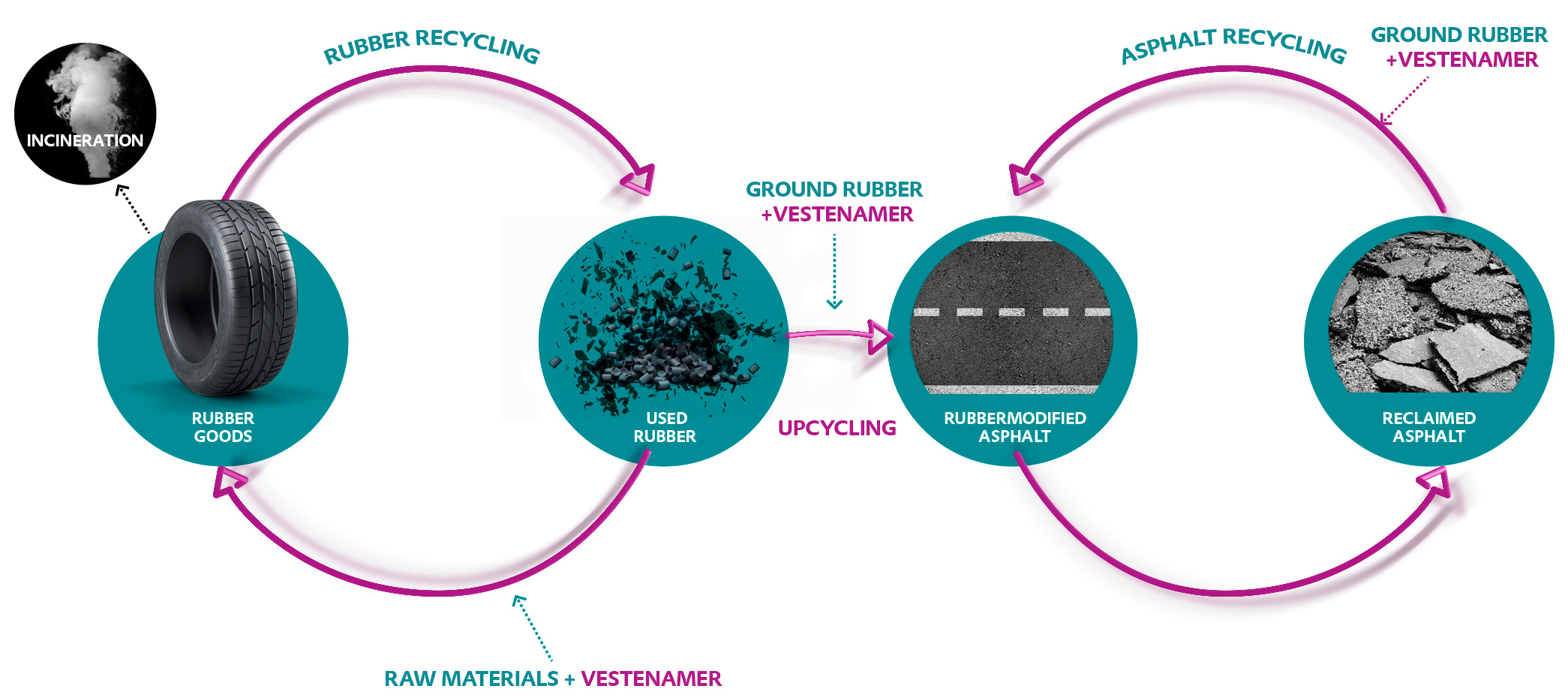

Each year, millions of tons of scrap tires are generated worldwide. Despite this enormous amount, rubber recycling is not yet standard practice. Most scrap tires are still incinerated, often in cement plants.

Rubber recycling involves transforming used rubber materials into new products. Commonly recycled rubber items include car tires, industrial rubber parts, and various other rubber products.

Transforming waste into value: Efficient rubber recycling powers the circular economy

By recycling rubber, natural resources are conserved, energy is saved, and environmental pollution is reduced. The recycling process involves several steps, such as shredding old rubber products, removing contaminants, and converting them into new, useful materials. Mechanical, chemical, and thermal methods are used to clean and reprocess the material.

The resulting recycled rubber compounds can be used in new products such as seals, mats, or modified asphalt mixtures, supporting the circular economy by turning waste into valuable resources.

High-Performance technologies for more efficient rubber recycling

Evonik provides innovative and effective solutions to enhance the entire recycling process. Our specially developed additives and catalysts increase the efficiency of rubber recovery and improve the quality of recycled materials. Leveraging our expertise in specialty chemicals, we ensure a higher purity and performance of recycled rubber compounds through advanced technologies.

A notable example of Evonik's commitment to rubber recycling is our VESTENAMER® additive. This technology enhances the thermal stability and processability of recycled rubber, enabling the production of high-quality products from scrap rubber. Through this approach, Evonik not only supports waste reduction but also fosters the development of sustainable production processes in the rubber industry.

Discover our circularity solutions in practice

Discover the transformative power of Evonik's Circular Economy program through our insightful case studies: Unveil how cutting-edge strategies and collaborations drive resource efficiency and sustainability across industries.