Our comprehensive application engineering advice also includes support from various CAE methods in the development of molds and molded parts.

In processing simulation, the injectionmolding process is calculated using stateof-the-art software from the filling phase through the holding pressure phase to the calculation of shrinkage and warpage. At the product development stage, information can be obtained on the

- Manufacturing process: for example, the ability to fill the tool, resulting process parameters, such as pressure and temperature distribution, cooling structures, influence of various processing parameters.

- Component properties: optimized position of weld lines and design suggestions to minimize shrinkage and warpage

- Manufacturing costs: size of machinery needed, cycle time, molded part/tool complexity

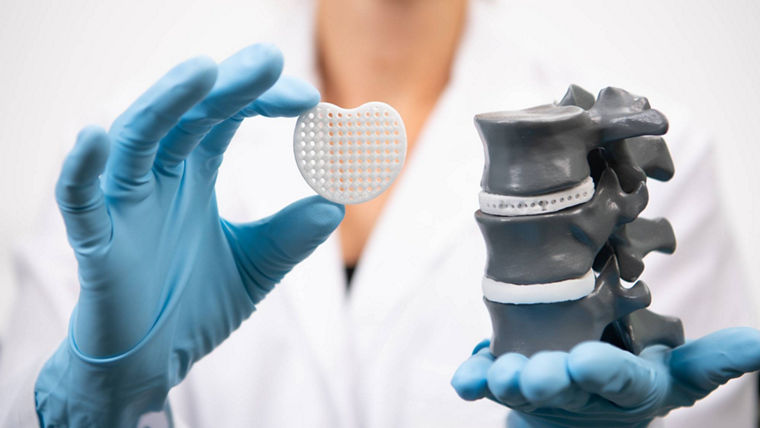

As a partner to our customers, we’re far more than just a manufacturer of high-quality polymers and semi-finished products. On the contrary, our goal is also to work hand-in-hand with our customers to develop next generation medical implant applications.

In other words, we

- develop a number of medical innovations jointly with our partners,

- advise on mold design for injection molding applications,

- provide intensive technical support about VESTAKEEP's material characterstics and performance

- help with the approval of new products

- provide machining guidelines for applications made of stock shapes

Implant-Grade

| Form | Delivery Form | |

|---|---|---|

| Granules | 1kg, 5kg and 10kg boxes with moisture-proof polyethylene liners | |

| Rods | Diameter*) 6-25mm 30-60mm 70-100mm | Standard lengths 3000mm 2000mm 1000mm + 2000mm |

| Powder | 10kg boxes with moisture-proof polyethylene liners1kg and 5kg boxes are also available upon request | |

| Plates | Width up to 500mm | Thickness up to 60mm |

*) Custom lengths are also available

Dental-Grade

| Form | Delivery Form | |

|---|---|---|

| Granules | 25kg boxes with polyethylene liners (2x 12.5 kg) *) | |

| Rods | Diameter**) 6-25mm 30-60mm 70-100mm | Standard lengths 3000mm 2000mm 1000mm + 2000mm |

| Discs | Diameter 98,5mm with notch 84,5mm without notch | Thickness 12-30mm 12-30mm |

*) Other sizes are also available

**) Custom lengths are also available

Care-Grade

| Form | Delivery Form | |

|---|---|---|

| Granules | 25kg boxes with polyethylene liners. | |

| Rods | Diameter* 6-25mm 30-60mm 70-100mm | Standard lengths 3000mm 2000mm 1000mm + 2000mm |

*) Custom lengths are also available

ANY QUESTIONS LEFT? JUST CONTACT US.

"Our global team of experts is ready to support you with all questions around VESTAKEEP® PEEK and its applications. Contact us to profit from more than 30 years of application know-how in the field of medical devices and find your individual solution!"

Dr. Philip Engel

Head of Segment Medical Systems Europe