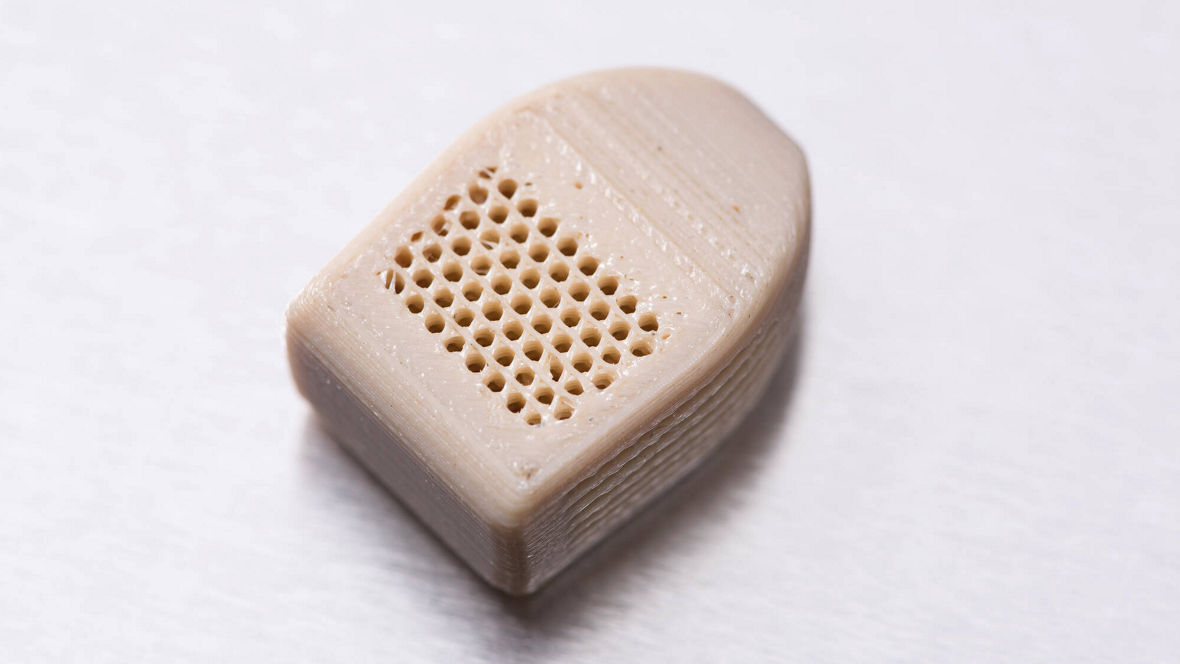

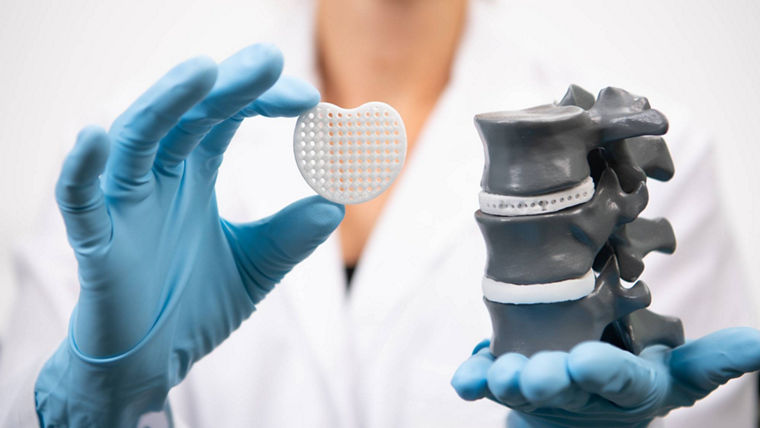

Evonik has become the first company in the world to develop a polymer filament based on PEEK (polyether ether ketone) in implant-grade quality for use as a 3D printing material for implants.

This high-performance material can be used in fused filament fabrication (FFF) technology and is expected to enable additive production of three-dimensional plastic parts for medical implants in the human body.

Product Overview

| Product name | Description | Diameter | Packaging | Download |

|---|---|---|---|---|

| VESTAKEEP® iC4612 3DF | Implant 3D printing grade with 12% carbon-fiber content | 1.75 mm | Transparent spools with 500g or 1,000g | |

| VESTAKEEP® iC4620 3DF | Implant 3D printing grade with 20% carbon-fiber content | 1.75 mm | Transparent spools with 500g or 1,000g | |

| VESTAKEEP® iC4800 3DF | Implant 3D printing grade | 1.75 mm | Transparent spools with 250g or 500g | Datasheet |

| VESTAKEEP® i4 3DF | Implant 3D printing grade | 1.75 mm | Transparent spools with 250g or 500g | Datasheet |

| VESTAKEEP® i4 3DF-T | Test and development grade | 1.75 mm | Deep purple spools with 250g or 500g | Datasheet |

Testing and Development grade enables cost-effective process adaptation

Evonik provides what is known as a “testing grade” version of its PEEK filament for fused filament fabrication (FFF) technology. The testing-grade material has the exact same processing and mechanical product properties as the implant-grade material—but without the documentation needed for approval in medical device applications. This offers a cost-effective way of adapting the processing characteristics of the high-performance plastic for printing processes.

Medical 3D printing grade

VESTAKEEP®i4 3DF is perfectly suitable for additive manufacturing using fused filament fabrication (FFF) technology. This PEEK filament is an implant-grade material based on VESTAKEEP® i4 G, a highly viscous, high-performance polymer from Evonik impressing by its

- biocompatibility

- biostability

- x-ray transparency, and

- easy handling.

The filament is manufactured in a clean and controlled environment and undergoes strict quality management for medical materials to meet the requirements of ASTM F2026 (the standard specification for PEEK polymers for surgical implant applications).

Whitepaper: Enhance patient recovery

No other market showcases the benefits of additive manufacturing as evident as in today’s medical technology.

Evonik and KUMOVIS, a 3D Systems company, explore the possibilities of 3D printing in medical technology for enhanced patient recovery.

ANY QUESTIONS LEFT? JUST CONTACT US.

"Our global team of experts is ready to support you with all questions around VESTAKEEP® PEEK and its applications. Contact us to profit from more than 30 years of application know-how in the field of medical devices and find your individual solution!"

Dr. Philip Engel

Head of Segment Medical Systems Europe