The biocompatibility of a medical device depends on the kind of body contact (contact to skin only, blood, fatty tissue, bone etc.) and on the duration of such contact. Therefore the biological evaluation of a medical device must be based on the intended application.

EN ISO 10993 provides a collection of international standards for biocompatibility testing and recommends how tests should be selected and designed to prove the biocompatibility of a device. Biocompatibility testing has always to be performed on the finished medical device because raw material selection, processing and combination determine the device’s biocompatibility.

In addition to EN ISO 10993, General Chapter <88> of the US Pharmacopeia (USP) describes tests on plastics for medical devices; depending on the application, plastics are assigned to Classes I to VI, those of Class VI having to satisfy the most stringent requirements.

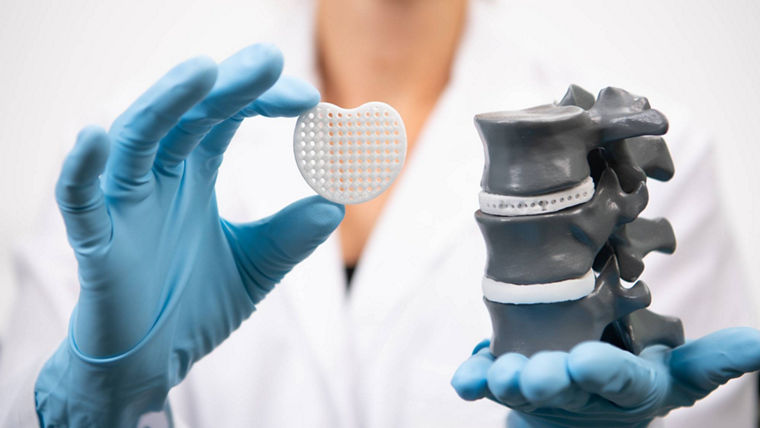

We offer VESTAKEEP® PEEK i Grades (permanent body contact) and VESTAKEEP® PEEK dental grades (for crowns, bridges, and removable dentures) as powder, granules and stockshapes as well as VESTAKEEP® Care for medical devices (e.g. surgical instruments). These products have been formulated to fulfil the needs and requirements of the Medical device industry. A comprehensive testing program performed on granules and stockshapes proved the high biocompatibility of VESTAKEEP® medical grade PEEK. To ensure a high level of safety of our materials, we run cytotoxicity tests according to EN ISO 10993-5 on every batch of resin and stock shapes.

All relevant information of the VESTAKEEP® i Grade polymers concerning manufacturing, consistency, and quality assurance has been registered in a Device Master File at the U.S. FDA.

VESTAKEEP® i grades are produced in a special process to achieve an even higher purity compared to the standard products. VESTAKEEP® i grades comply with ASTM F2026 “Standard Specification for Polyetheretherketone (PEEK) Polymers for Surgical Implant Applications”. Documentation, specification and quality assurance are adapted to the requirements of medical technology.

ANY QUESTIONS LEFT? JUST CONTACT US.

"Our global team of experts is ready to support you with all questions around VESTAKEEP® PEEK and its applications. Contact us to profit from more than 30 years of application know-how in the field of medical devices and find your individual solution!"

Dr. Philip Engel

Head of Segment Medical Systems Europe