Like parents: We teach liquids good behavior.

Rheology is the science of mastering the flow behavior of liquids. The highest discipline of rheology is thixotropy. Liquids with thixotropic behavior can change their structure from liquid to gel-like and back again. Nearly endlessly. Let us show you how this is the key to a convenient use of thousands of products.

Silica particles connect to all other ingredients in a formulation and build a three-dimensional network so that solids within your product do not settle.

Many products are a mixture of liquid and solid components. Nail polish, for example, consists of soluble binders, solvents, and solid color pigments. As the solid pigments have a higher density than the liquid phase, they sink to the bottom within a short period of time, which means the nail polish isn't usable without shaking.

Of course, you could add a firming agent to the varnish. It turns the liquid into a gel that “holds” the pigments in place. But a new problem occurs: The nail polish would be far too thick to use. This is the point where the thixotropy effect comes into play.

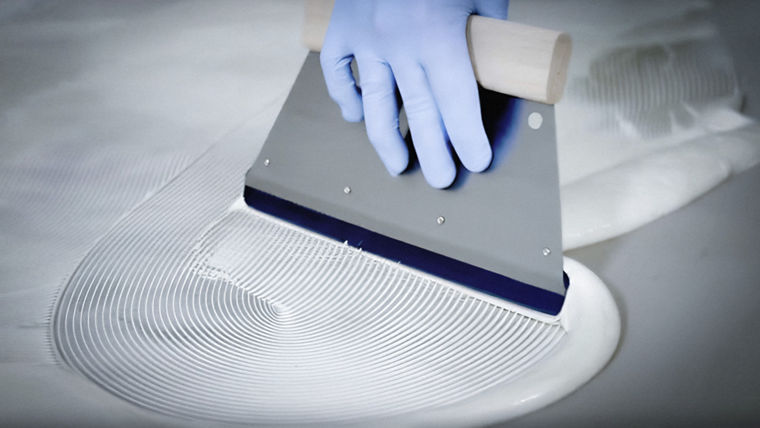

To achieve thixotropy, you use a product called silica, made of silicon dioxide (SiO2). Mixed into the liquid nail polish, the silica particles act like tiny “magnets”: They “connect” to all other ingredients in the formulation and build a network that gives the varnish gel-like stability and keeps the pigments evenly distributed. But that dynamic three-dimensional network is quite fragile. Under mechanical stress, for example, caused by a brush, the connections break and the nail polish becomes liquid again. It can be spread very conveniently.

Once on the nail, the non-Newtonian magic of thixotropy happens: The “magnetic field” is still there so that the three-dimensional dynamic network rebuilds within no time, the varnish becomes gel-like again and does not drip. So, you can color your nails precisely and without mess!

Nail polish is, of course, not the only example of the use of the thixotropy effect: When your toothpaste comes smoothly out of the tube, stays gel-like on your toothbrush, and becomes liquid again in your mouth, that’s thixotropy. Or think of silicone sealing mass: It leaves the cartridge fluidly but, in the joint, it becomes stable immediately until you smooth it with your finger. Thixotropy is used for all products that require fluid usage and a stable storage stability at the same time.

And finally, are you wondering, what that strange word stands for? Thixotropy comes from the ancient Greek language. A translation into English could be “touch-o-change”. And now everything makes sense …

Thixotropy is closely connected to silica. And silica is closely connected to our brands AEROSIL®, SIPERNAT®, and ZEOFREE®. We are the only producer worldwide of both fumed and precipitated silica. So, we can offer you a peerless variety of solutions for the precise rheology control of liquids.

So, what exactly happens within a liquid treated with silica? Let’s zoom in: Our silica particles have “arms”, and they take the neighboring ingredient “by the hand”. Within no time all ingredients are connected to each other and a stable, three-dimensional network from agglomerated silica aggregates is created. This network increases the viscosity, which means that liquids gain a gel-like stability.

- Solids within your product do not settle.

- Your product gains better storage stability.

At the same time your treated liquid is easy to process, because the silica network collapses under mechanical stress immediately. This means that when you stir, shake, or spread the stable gel, its viscosity decreases and it becomes liquid again. Chemists call this behavior “shear thinning”.

- Your product can still be processed smoothly.

- Consumers can use your product more conveniently.

Our silica products give you rheology control with only one ingredient: Usually, an addition of less than 1.5% is needed to achieve the desired effect. Unfortunately, rheology is a diva that must be treated very carefully. There are several points that can have a major impact on the efficacy of the thixotropy effect. Like the polarity of the fluid phase of the liquid. Or other additives, for example wetting agents. Furthermore, excessive processing can break the “arms” of the silica aggregates which can result in a reduction in the rheological properties due to the irreversible fragmentation.

But there is a solution to all those problems. We have 80+ years’ experience in the processing of silica, and our application experts are looking forward to assisting you to get the full potential from our products.

Silica gives you rheology control with only one ingredient: Usually, an addition of less than 1.5% is needed to achieve the desired effect.

When it comes to environmental aspects, there are also several points that speak for our rheology control products made from silicon dioxide:

- Energy: Thanks to the thixotropy effect, highly viscous liquids become smooth under mechanical stress so that less energy is needed for processing or bottling.

- Waste: Due to improved storage stability of your products, less waste can be expected.

- Health and safety: Our fumed or precipitated silica products have great effects on the rheology of your products – but they have nearly no effects on people and the environment: Silica is safe. That’s why they are even approved for use in food, feed, and pharmaceutical products. For example, the European Food Safety Authority confirmed the safety of silica as a food additive. Additionally, our silica products received an OMRI Listed® Certification, so they are proven suitable for organic farming. Please find further information on the safety of silica in our FAQs section.

Simply leave a message at ask-se@evonik.com or press the contact button below. Your request will be forwarded to one of our fumed silica specialists and they will get in touch with you as soon as possible.

Our clients, of course, will get assistance from their regional contact and from our application engineers. We are looking forward to hearing from you!

Those who wish to explore the topic in more depth can find further technical literature here:

Silica from Evonik are good rheology agents