AEROXIDE® Fumed Alumina serves a anti-settling agent in thermally conductive formulations

The Challenge

Thermally conductive formulations are based on material mixtures of a flowable and cross-linkable polymer matrix (silicone, polyurethane, epoxies, SMP, and acrylic-based others) and inorganic fillers that ensure thermal conductivity. These formulations are applied as thermal interface materials for efficient heat dissipation of electronic components e.g. in electrical vehicles.

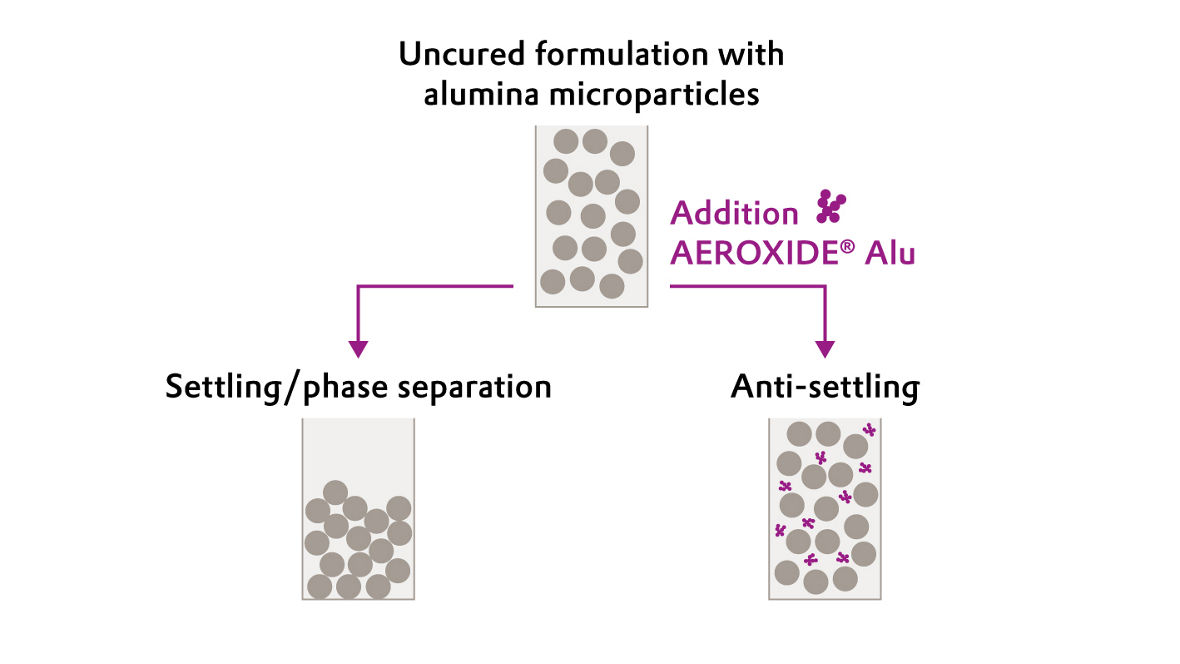

A major drawback is the pronounced sedimentation of the filler particles in the uncured formulation. This leads to an undesirable inhomogeneity of the particle distribution and a deterioration of the thermal conductivity of the formulation due to the phase-separated material mixture.

Evonik’s Smart Solutions

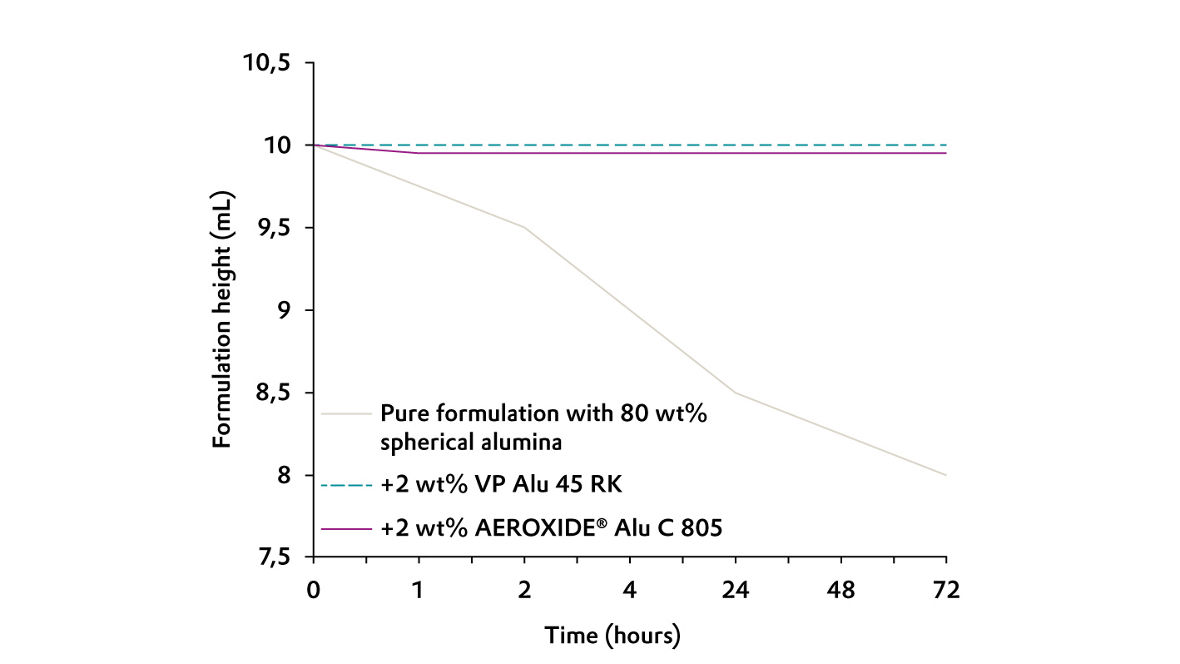

The key USP of Evonik’s AEROXIDE® fumed alumina is anti-settling of the main filler particles.

Evonik offers AEROXIDE® fumed alumina with different specific BET surface area, surface chemistry and aggregate size. They provide producers of thermal interface materials with a broad and efficient toolbox for tuning the rheology of the formulation at low dosage and inducing high thixotropy with low impact on high shear viscosity. The formulations show improved thermal conductivity and processibility, linked with higher shelf-life and stability.